In order to adapt to the development trend of industrialization in the construction industry, all parts of the system are produced in standardized factories. Except for a small number of anchor-based foundation construction, the site construction is mainly a block-type assembly operation. The construction, installation and maintenance personnel only need a small number of routine simple because of the limited energy level of the wire-rope-mesh stopper. It has been successfully developed to replace wire rope mesh with ring mesh which has more outstanding flexible characteristics and can change its geometric shape in the process of rockfall impact. Based on this, the rock block mesh can intercept rockfall more than 3000 kJ, and can further simplify the structural form (such as the configuration of supporting rope and pressure reducing ring) and is convenient. Maintenance and repair after partial damage has become a new type of stoneware (RXI) to replace the wire rope net system, which realizes the renewal and upgrade of the SNS passive protection system.

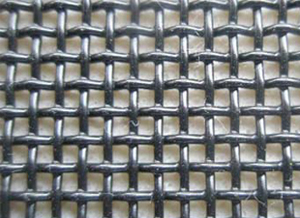

The ring net is made up of single steel wire, and the length between the ends of the two ends is not less than 100mm. Steel or aluminum alloy fasteners for ringsAt least three uniformly distributed hoops are tightened, and one of them is located at the lap of both ends, each ring is connected with its four peripheral rings except for the edge ring hole. The installation, maintenance and replacement of components can be carried out by single machine.

Advantage:

1. When the impact occurs, the ring hole can be geometrically deformed.

2, showing more superior flexibility.

3, more powerful energy absorption capacity

4, to achieve the kinetic energy up to 3000KJ above the rockfall interception

5. Greater flexibility.

6, smaller maintenance needs

7. Mutual looping between independent ring holes.

8. Replacement and repair after partial destruction is easier and more economical.